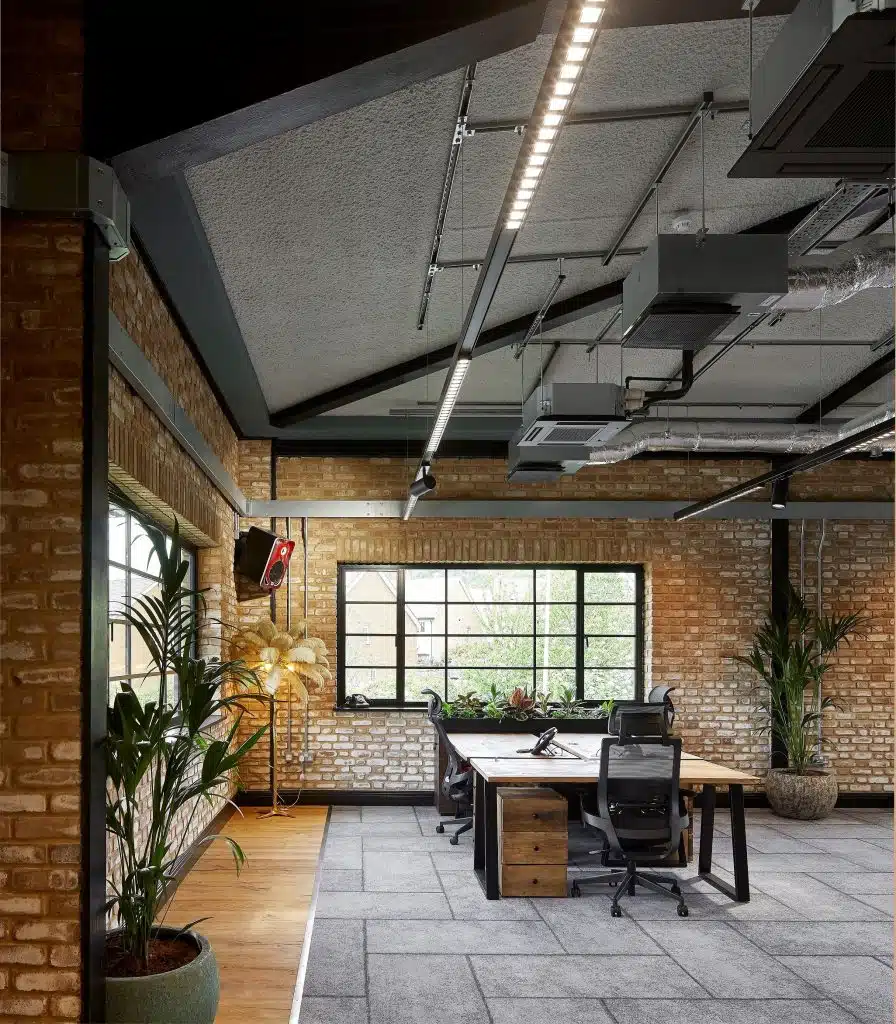

acoustic spray for seamless sound control

SonaSpray acoustic sprays deliver exceptional sound absorption while enhancing architectural detail. Ideal for both new builds and retrofits, SonaSpray offers a seamless acoustic finish that controls reverberation across a wide range of interior spaces. With a choice of colours, textures, and performance levels, our acoustic spray range gives architects and designers the freedom to create calm, comfortable environments without visual compromise.

Our acoustic sprays are installed by our in-house specialist teams and we cover all sectors across the whole of Great Britain. Get in touch with our acoustic experts today to discuss your project and get a quotation.

download image pack

Please fill out your details below to access our image packs.

You will need Adobe Acrobat Reader to view them.

Discover the versatile application capabilities of SonaSpray acoustic sprays through one of our high-resolution image packs, showcasing a range of environments.

Discover SonaSpray for:

- Commercial Spaces: Offices, boardrooms, reception areas.

- Education: Schools, universities, classrooms, lecture theatres, libraries.

- Hospitality: Restaurants, bars,music venues, hotels.

- Public spaces: Cultural Buildings: Museums, galleries, theatres.

- Industrial: Warehouses, manufacturing plants, big sheds, showrooms.

acoustic spray product showroom

Our state-of-the-art HQ – the Oscar Innovation Centre – in Halling, Kent, showcases our SonaSpray acoustic spray range in a real-life setting. Only 20 minutes by train from London, we invite our valued customers to book a tour to view our full product range in a real-life setting.

By booking a tour you will get a real sense of how acoustic spray can visually and acoustically transform your next project. Get in touch to book a tour for yourself, your design teams and potential clients to view our products in situ and see and hear them come to life.

Should you wish, our managing director, Ben Hancock, also offers a ‘Detailing of Acoustic Finishes’ CPD at the end of the tour, providing you and your teams with expert insights into how our acoustic solutions can work for you.

acoustic spray frequently asked questions

Our SonaSpray acoustic sprays are seamless, spray-applied finishes designed to reduce noise levels and improve sound quality within interior spaces. Made from a blend of natural cellulose fibres including wood, cotton, hemp and other rapidly renewable resources, SonaSpray absorbs sound instead of reflecting it, significantly reducing noise reverberation in any space.

Unlike conventional panels or blocks, SonaSpray acoustic spray systems can be applied directly onto most substrates, including concrete, metal decking, timber, plasterboard, and more. Its seamless application allows for coverage across flat, curved, vaulted, and irregular surfaces, making it a favoured choice in open-plan spaces and exposed soffit designs.

Thanks to its adaptability and performance, acoustic spray can be used in a wide range of settings:

- Commercial: Offices, showrooms, boardrooms

- Hospitality: Hotels, restaurants, bars

- Entertainment: Film studios, concert halls, arenas

- Retail: Shopping centres, high street stores

- Education: Schools, universities, libraries

- Cultural and Civic: Theatres, museums, town halls

- Industrial: Warehouses, production spaces

It is especially effective in buildings with exposed soffits and hard surfaces where traditional acoustic products may be impractical.

Acoustic spray must be installed by specialist trained, qualified professionals due to its specific equipment and expertise requirements. The process typically includes:

- Surface Preparation: Ensure the substrate is clean, dry, and structurally sound.

- Masking and Protection: Areas not being sprayed are carefully masked to protect fixtures and finishes.

- Spray Application: Material is spray-applied to achieve the desired thickness and finish.

- Final Inspections: Allow sufficient time for drying and conduct post-installation inspections for quality assurance.

Installation is generally quicker than constructing suspended ceilings or affixing panels, especially in large, open areas.

Maintaining acoustic spray is really easy using a soft brush and vacuum cleaner. This prevents any damage to the walls/ceilings you are maintaining.

Our acoustic sprays are within reason, quick and easy to locally and invisibly repair. We can train contractor labourers to do this and can also provide a video to demonstrate. Most acoustic sprays on the market require pre-handover re-sprays to deal with any damages. In some cases, this requires putting up bird cage scaffolds again.